Our Clients

GALLERY

SOME INSTALLATIONS

LOGISTICS

| Key Information about our Standard Model | |

|---|---|

| Load Capacity | 1800 kg |

| Loading Height Range | 500-2000 mm |

| Pallet Type | Up to 1200 x 1200mm |

| Production | Up to 35 pallets/hour |

| Origin | Argentine Industry |

| Maintenance and After-Sales Service | Fademaq |

PALLET EXCHANGER - IPV1820

Our most emblematic machine. Of maximum quality and operational effectiveness.

The pallet exchange with the IPV1820 is carried out through an automatic cycle without the need for unloading and reloading the cargo (manually moving the cargo from one pallet to another), generating multiple benefits:

Our Standard Model can be Adapted to meet the customer's operational needs.

| Key Information about our Standard Model | |

|---|---|

| Load Capacity | 550 kg |

| Quantity of Pallets | 15 units |

| Pallet Type | 1200 x 100mm |

| Origin | Argentine Industry |

| Maintenance and After-Sales Service | Fademaq |

PALLET DISPENSER - DPA1215

Pallet Organizer. Avoids the risks of its manipulation.

Its automatic operation, with the assistance of an electric pallet jack or forklift, results in the safest and most orderly way to organize pallets:

Our Standard Model can be Adapted to meet the customer's operational needs.

| Key Information about our Standard Model | |

|---|---|

| Load Capacity | 800 kg |

| Loading Height Range | 500-2000 mm |

| Pallet Type | 1200 x 1000mm |

| Origin | Argentine Industry |

| Maintenance and After-Sales Service | Fademaq |

PALLET EXCHANGE DEVICE - DIP 1830

Mechanical Pallet Exchange System.

With distinctive features and specific scopes, the DPA 1830 offers multiple benefits that ensure:

Our Standard Model can be Adapted to meet the customer's operational needs.

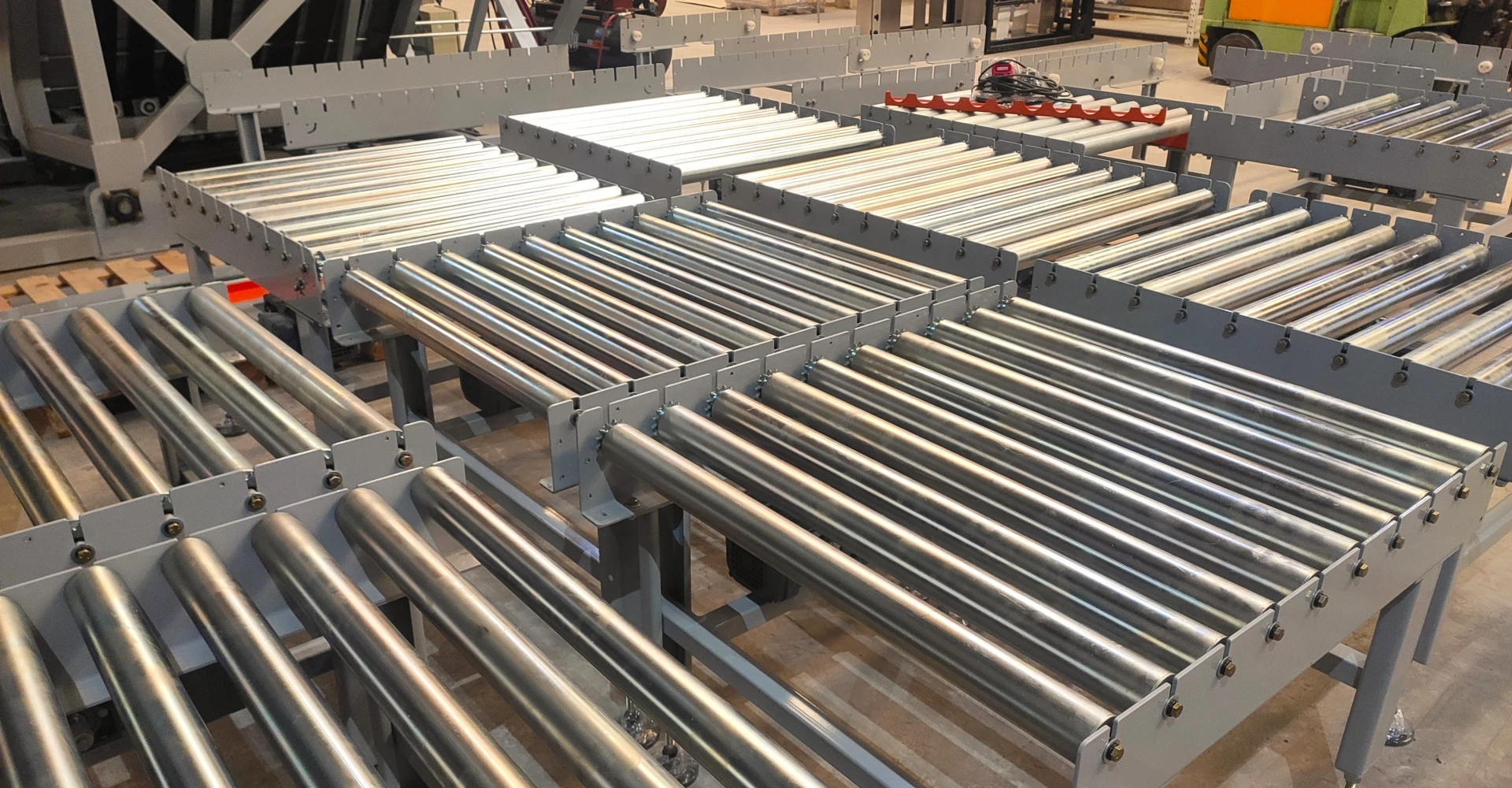

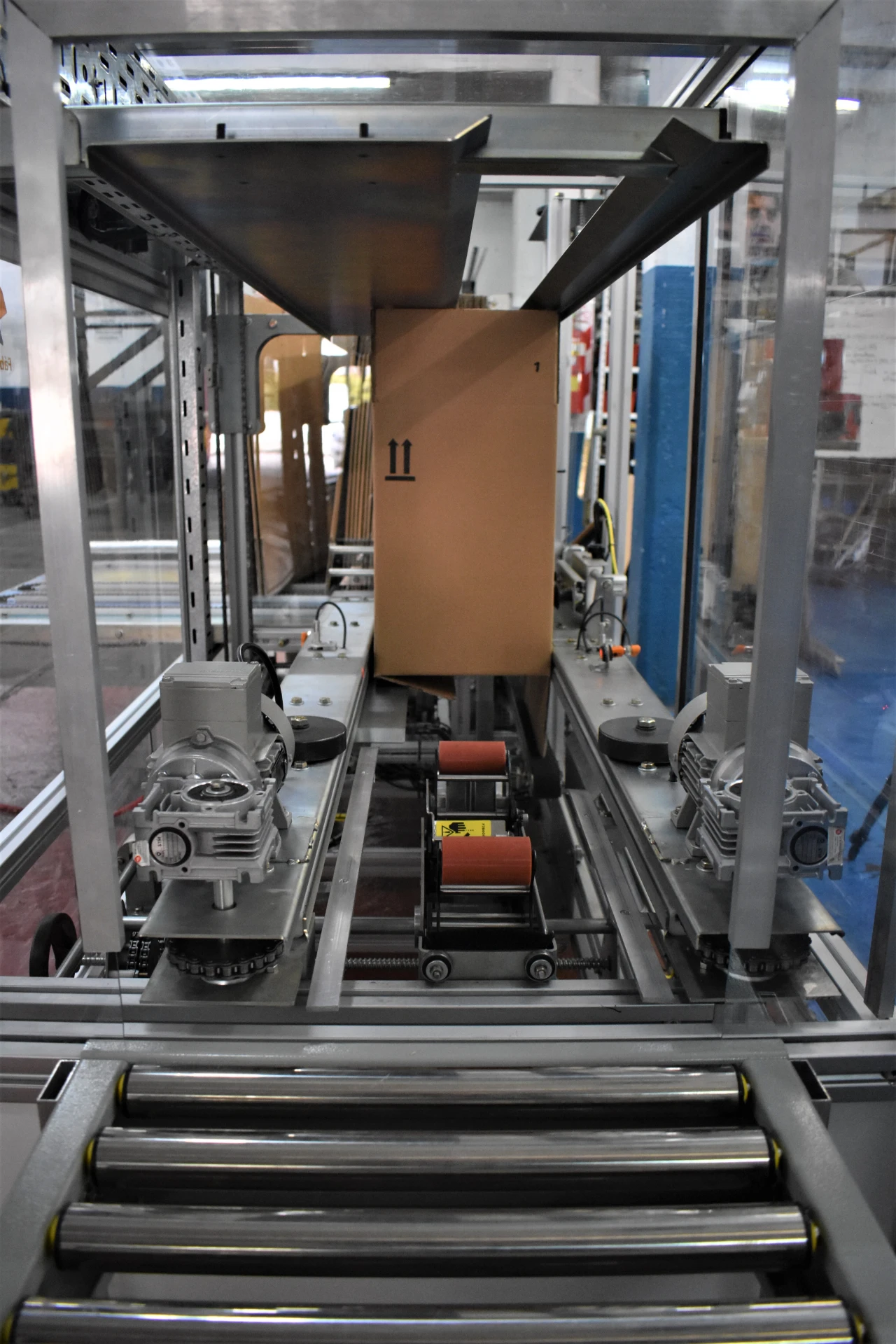

TRANSPORTATION in PRODUCTION LINES

Efficient and safe movement of goods and products.

Through the transportation system, we achieve:

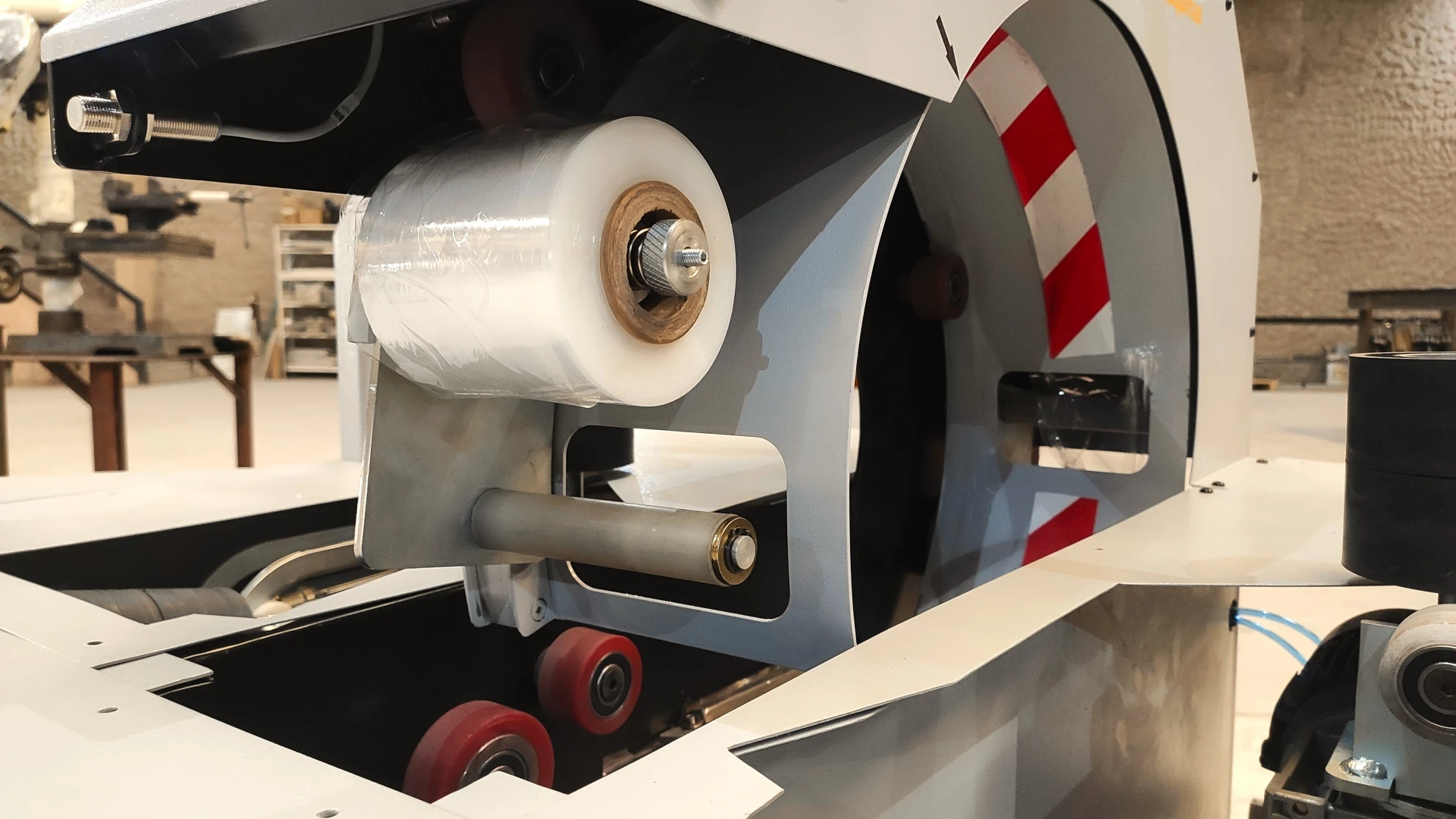

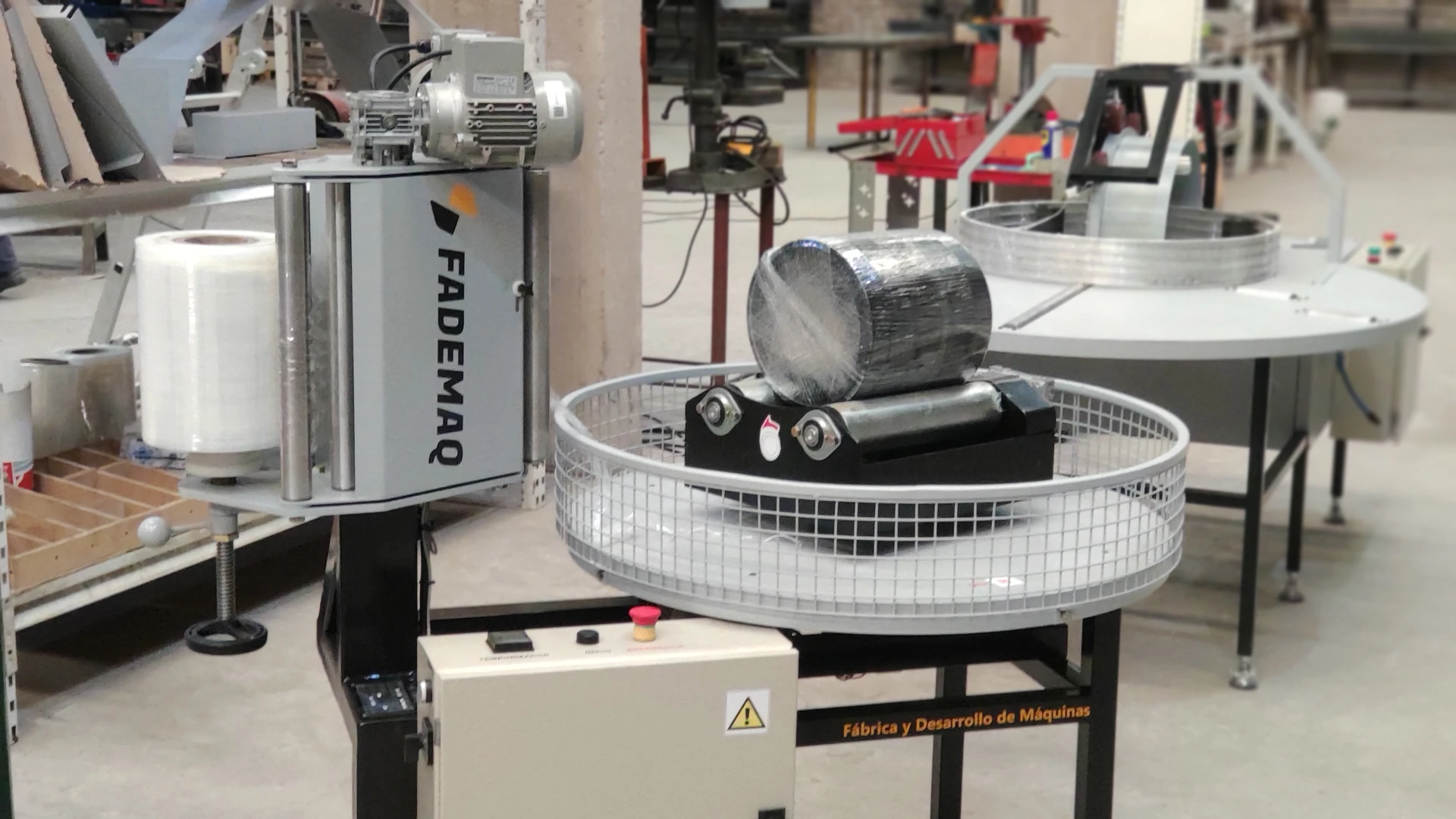

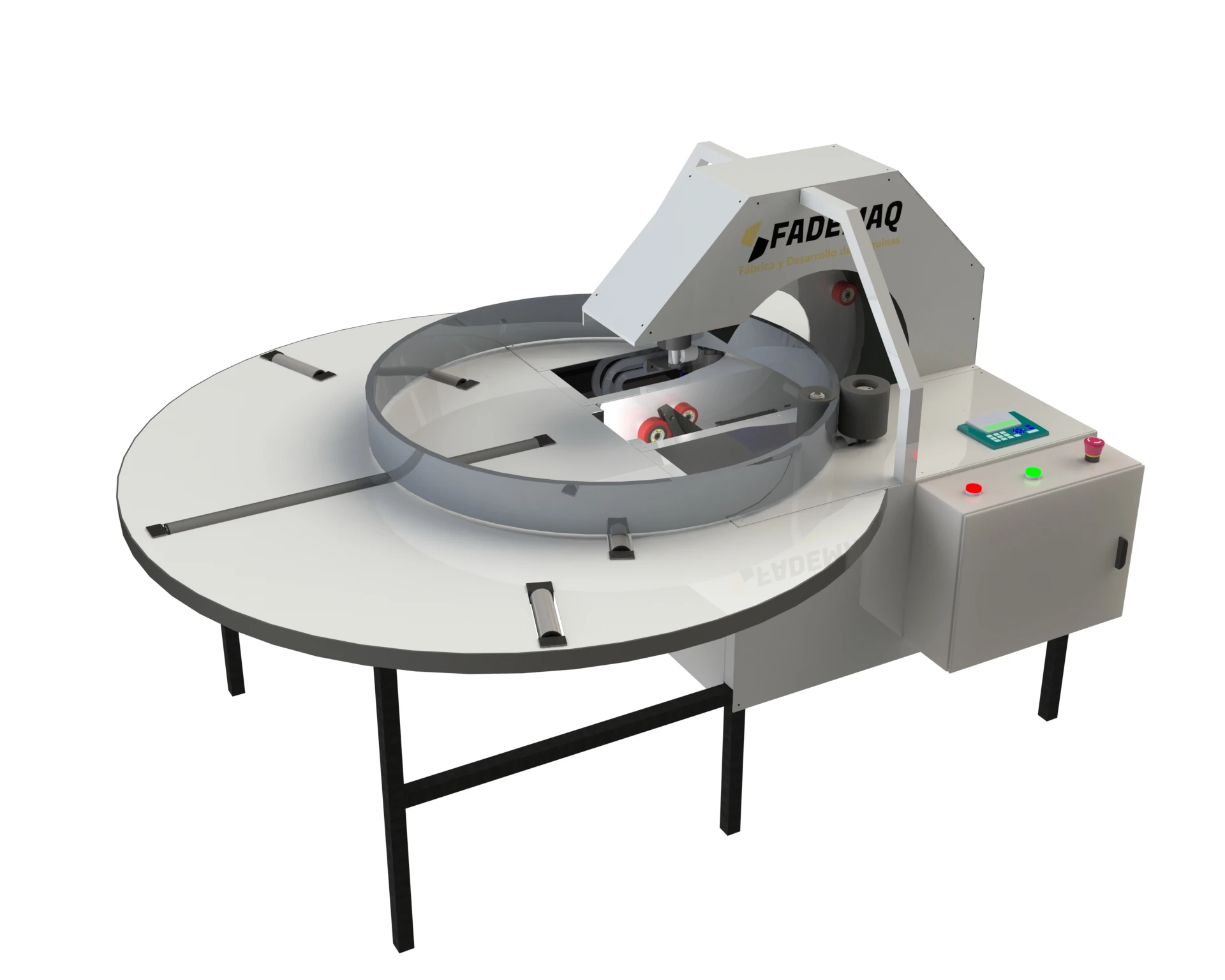

PACKAGING

END OF LINE PRODUCTION

Automated resources that optimize productivity.

We have solutions capable of minimizing the burden produced by the repetitive activities characteristic of preparing products for dispatch and distribution, thus giving productivity a boost.

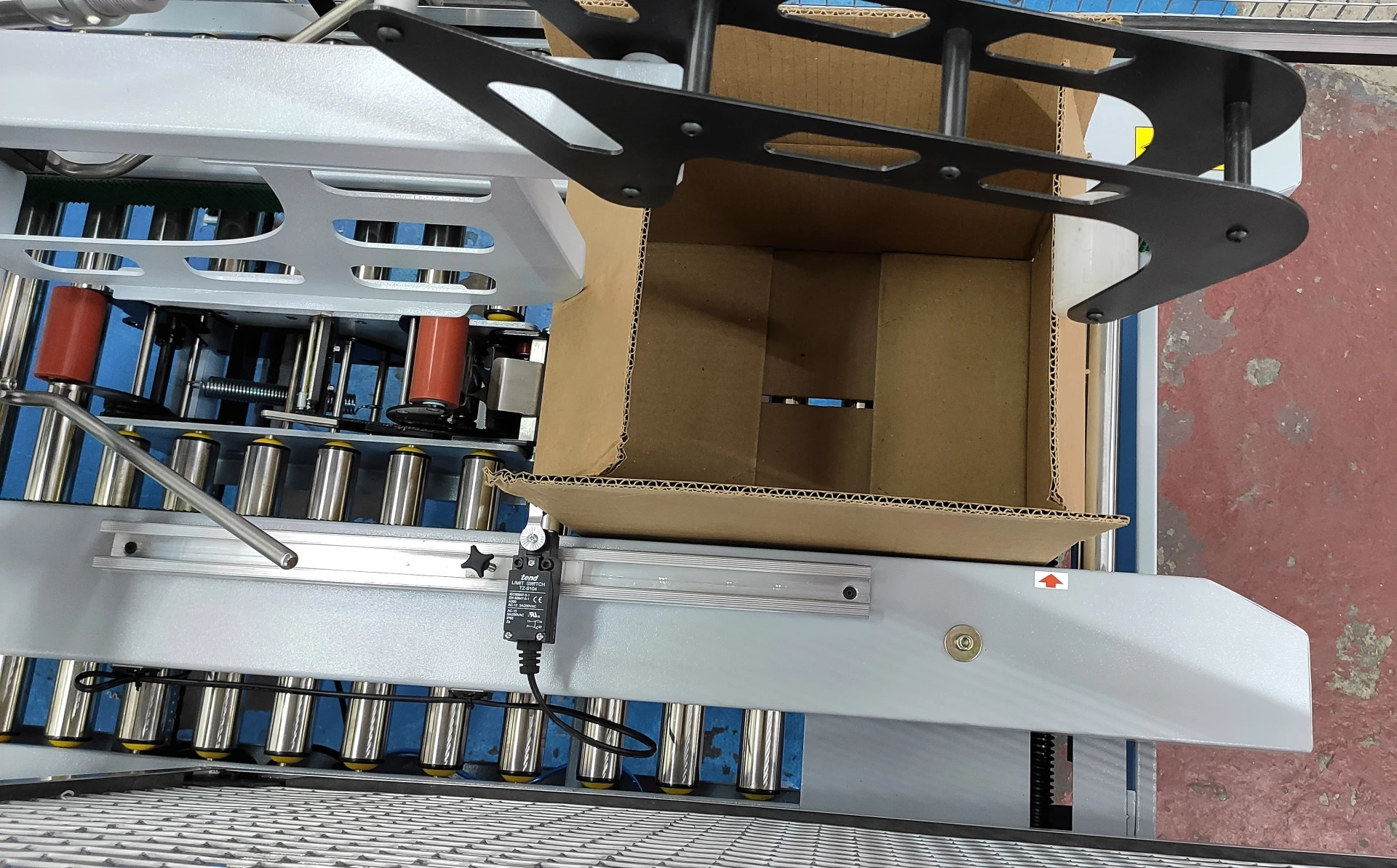

BOX ON DEMAND (CUSTOM BOX CUTTER)

ALL IN ONE SOLUTIONS

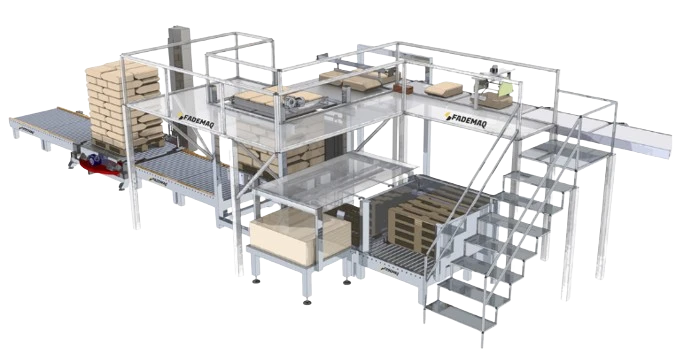

TURNKEY PROJECTS

Your reliable partner in the implementation of large projects.

We conceive comprehensive projects that involve our different areas, assuming with a holistic approach the tackling of the entire process: from planning and design to construction, installation, and commissioning.

About Us

Fademaq is a company specialized in the development and manufacturing of machines for logistics and merchandise dispatch.

Our flagship product is the PALLET EXCHANGER, recognized as a benchmark in the market, and from there, NEW DEVELOPMENTS related to it have been added, enriching the LOGISTICS AREA. Additionally, we have specialized in merchandise TRANSPORT devices in PRODUCTION LINES and in the manufacturing of machines for PACKAGING. Working in collaboration with leading companies in the sector, we can offer complete TURNKEY PROJECTS, implementing comprehensive improvements. We strive to establish TRUST relationships with our CUSTOMERS, becoming a strategic partner that understands their challenges and provides solutions tailored to their NEEDS.

Our Services

We are present at every stage alongside our clients

Consulting

We analyze operational needs to define the appropriate equipment for our clients:

Starting from our portfolio of machines, we offer the possibility of modifying our standard models; and we even have the option to design, develop, and manufacture a new machine.

Design and Manufacturing

Our trajectory and experience allow us to analyze and propose new developments to our clients, beyond our product portfolio, manufacturing customized solutions.

Commissioning and Training

Our team leads the installation process up to the final verification of the equipment's optimal operation.

Training is a key process that ensures users and technicians responsible for the machine are prepared for effective and safe use.

Technical Assistance and Maintenance

In case of a technical problem or difficulties during the use of our machine, we provide technical assistance through various available communication channels or through on-site visits to our clients' facilities.

Furthermore, we ensure a long lifespan of our machines through Maintenance services: whether preventive or for repairing unforeseen breakdowns.

Contact Us!

Location

1710 Street 3360

Our latest news online

Follow us on our social networks